Beaconsfield, Tasmania, Australia.

Two weeks of tension. Two weeks of media circus. Two weeks of waiting. Two weeks trapped in a six foot by four foot cage, in pitch blackness. Two weeks of struggling and striving to get them out, using the latest, totally new technique, developed on the fly by tough, courageous men who put their lives on the line for their mates. Two weeks while a whole nation watched and fervently prayed that they would get out alive.

The town transformed. Media everywhere. Miners striving. A journalist dies of heart failure. And then, they’re out! And a nation rejoices! From the least to the greatest, Australia is glad for Todd and Brant. Sad, though, for Larry, who didn’t make it, and for his family. History is made. And the mine rescue text books will have a new chapter.

Beaconsfield, Tasmania. The town has a long and interesting story to tell long before the events of Anzac Day 2006. The first gold was found in the Tasmania reef, near where the present mine is today, in 1877 by the Daly brothers. From then to 1914 26 tonnes of gold was produced from the mine. They took the mine down to 1500 feet (461 metres) before they had to stop. The problem was that old mining problem of water. Water was flooding the mine workings.

If you think about it, a deep mine is just like digging a huge well. Water comes into the well and you get some out when you need it. But a gold mine is there to get out gold, and the water is a nuisance that prevents the mine from operating. So you have to get it out. And there’s lots to get out! So they decided to invest heavily in pumping equipment. They built three huge pumps, which could take out eight million gallons of water every day – thirty six thousand tonnes of water every day! They were some machines for 1905! When you inspect the remains of this machinery, and the working models that operate at the very impressive museum, you are left in awe of the work that was achieved with the very limited gear they had 100 years ago.

Beaconsfield at the time was a large and prosperous town – they reckon it was the third largest in Tasmania, after Hobart and Launceston. Lots of pubs (of course!), churches, shops and schools. It even had its own port at Beauty Point, about 10 kms away, with a steam train service running between them. The mine was obviously successful – just look at the quality of the mine buildings they built that are still standing today.

But by 1914 it was just not economic to keep on going, so the mine was abandoned. The water problem was just too much. Just at the beginning of World War 1 the mine shut, and the town went to sleep for about 80 years. By the 1920s mine tunnels collapsed, closing one of the two shafts, the Grubb shaft, completely. You can see two sets of pump rod ends at the top of the remains of the Grubb shaft in the photo. Each of those pump rods weighs 200 tonnes and is 454 metres long! Only the Hart shaft remains, and that is the one in use now.

In the early 1990s planning started to get the Beaconsfield gold mine underway again. New technology meant that de-watering is not as much of a problem as it was 80 years ago. By 1999 the first gold ingot was poured, and the gold mine has been operating ever since. At least up until that Anzac Day, April 25, 2006, when an earth tremor caused a rock fall, and of the 17 men underground at the time only 14 made it to the surface. Three men, Larry Knight, Brant Webb and Todd Russell, didn’t. The mine management immediately began rescue operations, beginning with a remote control loader. Sadly, after a time, they found the body of Larry Knight.

It soon became obvious, though, that using the remote controlled loader wasn’t safe anymore because of the danger of more rockfalls. By this time contact had been made with Brant and Todd, and it was learned that not only were they alive, but they were in reasonably good health. Food and water, as well as torches and batteries, clothes and reading material, deodorant (which they probably needed by then!) and toothpaste, as well as some iPods, were passed down to them through a 90mm PVC pipe. What must have pleased them most were letters from their families – and they also had the chance to send letters back.

One miner actually scrambled across the rubble that was over the machine that they were trapped in, and got close enough to shake Todd’s hand. But both Todd and Brant didn’t want the rescue to come that way, because then they would have to cut the wire mesh on the side of the cage, and that was already under a lot of tension from the weight of rock against it.

The mine management had to have a major rethink of the way they were going to rescue them, and eventually they decided to use a Raise Borer to bore a 1 metre diameter hole from another tunnel about 14 metres away. They had to get this machine from a mine near Queenstown on the west coast of Tasmania, which took some time, and then they had to set it up, which included pouring concrete foundations which had to set. But they couldn’t hurry it. The job had to be done, and it had to be done properly. There was no point in putting other people’s lives at risk as well.

A raise borer works by first drilling a small diameter pilot hole – in this case about 200 mm (8 inches) which the main borer follows. This is a similar procedure to that used on a much smaller scale by engineers around the world when using large drill bits. Drill a small hole with a small drill bit and it both guides the larger drill bit and makes the drilling operation much easier. The whole job took about 3 days to finish. The trouble was that the rock they were boring through was about 5 times harder than concrete, plus they didn’t want to push the machine too hard because they didn’t want to cause another rock fall. So instead of cutting at about 1 metre per hour, which is the Raise Borer’s maximum, they could do less than half that rate – about 460 mm per hour.

These guys are professional miners and knew just what they were doing, but the tension down there must have been enormous. Remember that they were nearly 1000 metres underground, measured vertically. That’s more than twice the depth of the original mine, and nearly one kilometre down!

At the end of three days they took the raise borer apart and removed it from the tunnel. Then they attempted to cut further into the last bit using diamond edged chainsaws. The rock was so hard they were not making any real progress, so instead they decided to use low impact explosives. An expert in low impact explosives had come from Victoria, and he very carefully placed and set the charges. For the last bit they were lying on their backs working – drilling, clearing rubble, setting and fixing charges, and then leaving the tunnel until the charges had gone off. Then more clearing rubble, and more drilling … these are tough men who know what it is to work in hard conditions. But their mates were trapped so they did whatever it took to get them out.

Finally, after 14 nights, two whole weeks, they got through. Brant got out at 4.47 on Tuesday morning May 9, and Todd 7 minutes later at 4.54. After being checked by doctors, and having had showers, they went to the surface at two minutes to six that morning. They walked straight over to their safety tags and turned them to ‘safe’ and then embraced their families. A nation’s prayers were answered, and answered in the best way possible.

This rescue will no doubt go into the mine rescue textbooks as well as into mining history. And how are Todd and Brant? According to one local I spoke with last week they are still recovering. They have some pretty serious injuries to contend with – leg injuries, back injuries including damaged vertebrae, and neck injuries. These will take time to heal, but the psychological issues they face will take longer to heal. Both men have been generous with money they received from selling their stories, setting up a foundation with which to help their fellow miners. They have not forgotten those who put their lives on the line to get them out.

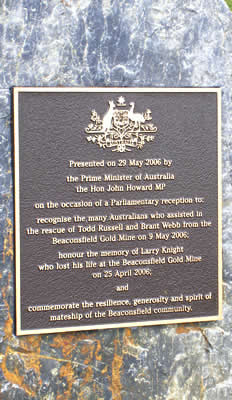

Plaque presented by the Prime Minister of Australia, Mr John Howard, in commemoration of the Beaconsfield Gold Mine Rescue.

This page Copyright © ThisisAustralia.au

All the labels you use every day, with excellent service! EveryLabels.com.au